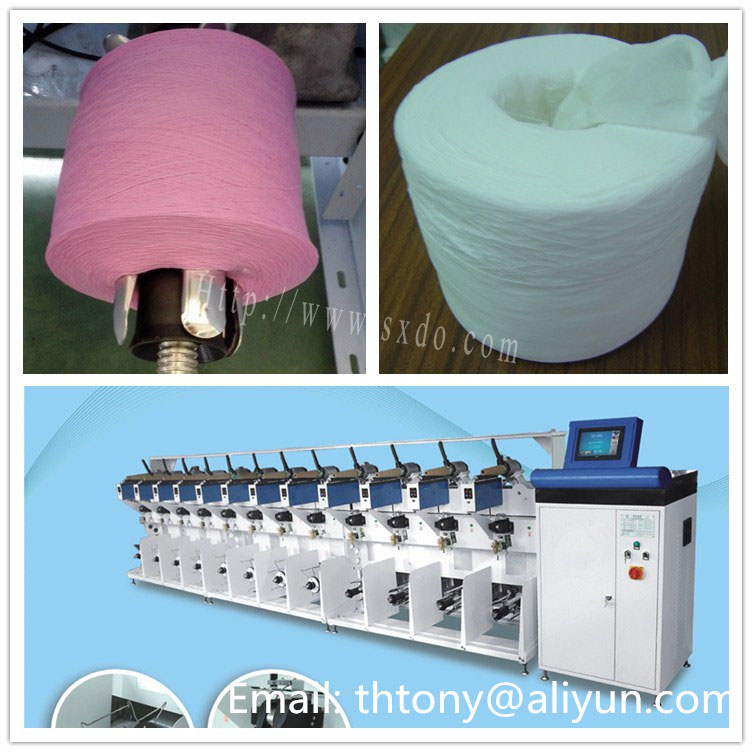

TH-11B Hank to cone winder machine

Machine Introduction:

TH-11B Hank to Cone Winding Machine is applied with the most advanced technology of unwinding actively in the world. It introduces the yarn loading tension control technology from Europe to make the yarn tension steady even while winding, which can make the tension same both inside and outside. Besides, it can also set the tension as required to improve the yarn quality and production efficiency. This technology provides the perfect solution for the yarn which cannot be unwound. It realizes the dream of dyeing and winding directly after texturing. The Hank is positive turning to feeding the yarn, so it can be max working at 1000 Meer/min, with BTSR online sensor, so the yarn tension can be controller very well automatic.

|

Types of winding |

precision winding/Electronic winding |

|

Mechanical speed |

up to 1000m/min (process speed depending on process parameters) |

|

Package shape |

Freely Programmable |

|

Traverse length |

30-250mm |

|

Take-up package diameter |

180 to 200mm |

|

Package weight |

up to 2kg |

|

Supply package diameter |

up to 320 mm |

|

Suitable Yarns |

Nylon, Filament yarn, Wool yarn, Acrylic yarn, Polyester yarn, Spun thread and etc. |

|

Take up bobbin |

0°-5°57'; |

|

Layout |

single side machine |

|

Number of spindles per section |

4 spindles |

|

Max. spindles per set |

60 Spindles |

|

Gauge |

450mm |

|

Drive |

each spindle individual |

|

Hank Turning |

Positive turning to feed the yarn |

|

Installed power |

~380w per spindle |

|

Power consumption |

~136w per spindle |

|

Density of winding |

Freely programmable |

|

Online sensor |

Installed BTSR sensor |

|

Size per section (L*W*H) |

1823*700*1550mm |

Product tag: Hank to cone winding machine, Nylon yarn winding machine,precise winding machine