TH-16 Pneumatic Hank to cone winder

Machine Introduction:

TH-16 High speed Hank to Cone winding machine, it applied the most advanced technology of positive unwinding in the world, installed the BTSR sensor for online tension and Pneumatic driving hank, can make the yarn tension more steady even in high speed winding, it's easily to operate the machine, can reduce the yarn waste when rewinding yarn from hank to cone.

|

Types of winding |

precision winding/Electronic winding |

|

Mechanical speed |

up to 1000m/min (process speed depending on process parameters) |

|

Package shape |

freely programmable |

|

Traverse length |

155-210mm |

|

Take-up package diameter |

180 to 200mm |

|

Package weight |

up to 2-3kg |

|

Supply package diameter |

up to 450mm |

|

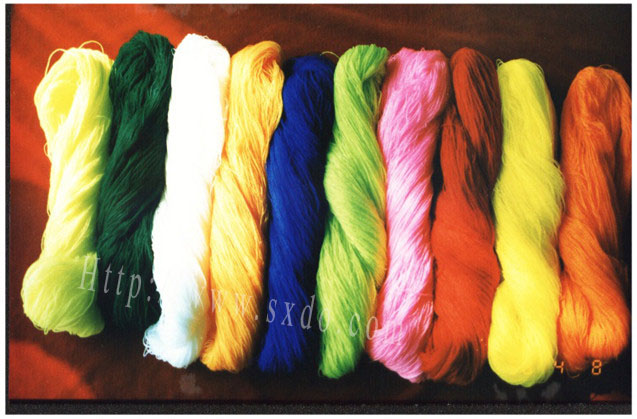

Suitable Yarns |

like polyester, DTY, FDY, Acrylic yarn, Cotton, Wool yarn, Sweater yarns and etc. |

|

Take-up tubes |

Tube bobbin - 5°57' Conical cone |

|

Layout |

single side machine |

|

Number of spindles per section |

4 spindles |

|

Max Spindle per set |

40 spindles |

|

Gauge |

400mm |

|

Drive |

Each spindle Driving individual |

|

Installed power |

~500w per spindle |

|

Power consumption |

~55w per spindle |

|

Density of winding |

Freely programable |

|

Pneumatic hank |

max Perimeter 1540 mm |

|

Size per section (L*W*H) |

2150*900*1980mm |